|

|

|

Ultrasonic Cleaning Machines

|

• Theory

|

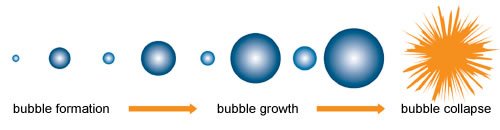

Ultrasonic cleaning machine works mainly through the transducer, which converts the electrical energy to high frequency mechanical energy vibrating, to produce alternating high and low pressure waves within the cleaning liquid. Due to the ultrasonic radiation, so that the liquid in the tank under the action of micro-bubbles can be kept to a sound wave vibrations.

When the sound pressure or sound intensity under pressure reaches a certain level, the bubble will quickly inflate and then suddenly collapse. During this process, the closing moments of the bubble generated shock waves to make bubbles generated big pressure, this enormous pressure generated by the ultrasonic cavitation can destroy insoluble contaminants in the solution and allow them to differentiate, steam-type cavitation repeated impact directly on the dirt.

There are many factors affecting the cleaning effect including cleaning temperature, ultrasonic frequency, ultrasonic power, cleaning time, cleaning agent, etc.

The suitable temperature can improve the cavitation in liquid. It is also important to choose a best cleaning agent designed to

work with ultrasonic cleaning machine for the best result.

Each ultrasonic operational frequency has its own unique characteristics, these characteristics can be used to determine which frequency is suitable for cleaning objects.

So as to meet the needs of customers, we offer many types of cleaning machines as follows: |

|

» Benchtop Ultrasonic Cleaners |

|

|

| » Industrial Ultrasonic Cleaning Equipment |

| » Ultrasonic Immersible Transducers |

| » Ultrasonic Rod Transducers |

» High Power Ultrasonic Cleaning Machines

|

|

• Applications

|

|

|

1) Ultrasonic cleaning for electronic industry

|

|

|

- Printed circuit boards (PCB);

- Electric parts;

- Magnetic materials;

- Semiconductor elements;

- Capacitors;

- Ceramic substrates; |

|

2) Ultrasonic cleaning for machinery manufacturing

|

|

|

- Hydraulic, pneumatic components;

- Mechanical parts;

- Bearing parts;

- Plating parts;

- Gears;

- Assemblies; |

|

3) Ultrasonic cleaning for automotive industry

|

|

|

- Motor vehicles parts;

- Spark plugs;

- Carburetors;

- Fuel injectors;

- Fuel pumps;

- Accumulator electrode;

- Engines; |

|

4) Ultrasonic cleaning for hardware tools

|

|

|

- Moulds;

- Cutting tools;

- Measuring tools;

- Carbide tools;

- Abrasives;

- Screen mesh;

|

|

5) Ultrasonic cleaning for petrochemical Industry

|

|

|

- Heat exchangers;

- Containers of chemical reagent;

- Chemical fiber spinnerets;

- Chemical containers;

- Metal filters; |

|

6) Ultrasonic cleaning for jewelry industry

|

|

|

- Metal ornaments;

- Gold and silver ornaments;

- Jewelry;

- Jades;

- Chains;

- Coins;

- Watches; |

|

7) Ultrasonic cleaning for optic

|

|

|

- Optical glass;

- Cylindrical lens;

- Prism;

- Aspherical mirror;

- Optical filter;

- Contact lenses; |

| |

|

↑ Top |

|

Downloads

Downloads Sitemap

Sitemap Downloads

Downloads Sitemap

Sitemap