|

|

|

|

Ultrasonic Anti-scaling Processors

|

|

• Principle

|

The scaling problem is the most challenging. The result indicates that the prevention and removal of scale is feasible by ultrasonic anti-scaling processors.

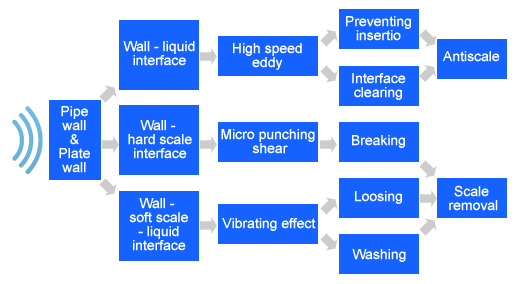

When ultrasonic wave travels through pipe wall or plate wall, the shock wave occurs and generates high speed eddy in liquid, to prevent the scale formation. On the other hand, the shear stress can be formed between scale and metal wall, it will change the properties of scale, and finally make it disperse, crush, loose and shatter.

|

• Feature

|

- Ultrasonic descaling and antiscaling can run at the same time.

The ultrasonic processors can remove at once and prevent deposition of scale for long term.

- Low power consumption, low operating cost.

Variable peak output power and completely free maintenance.

- Three layers automatic protection, safe and reliable.

Automatic protection of overcurrent, overvoltage and overheating, the ultrasonic anti-scaling processors adopt intelligent control, which is safe and reliable.

- Humanized design and automated control.

Ultrasonic generator has function of automatic frequency tracking, which can monitor the working status of equipment, and follow response timely. When ultrasonic anti-scaling processor is under the no-load condition, it will send out sound and light alarm signal, then cut off the power to protect equipment.

- Cleaner and greener.

There is no need to use any chemicals in the whole process of descaling and antiscaling, which means no corrosion, no interference, no pollution, no radiation and has no damage to operators and heat exchange equipment.

|

|

• Application

|

|

| |

|

|

|

|

|

| |

Ultrasonic descaling & anti-scaling for cooler in chlor-alkali factory. |

|

Ultrasonic descaling & anti-scaling for condenser system in thermo-electric plant. |

|

|

| |

|

|

|

| |

|

|

|

|

|

| |

Ultrasonic descaling & anti-scaling for H-type steel workshop in steel factory. |

|

Ultrasonic descaling & anti-scaling for dust-removal system in steel mill. |

|

|

| |

|

|

|

| |

|

|

|

|

|

| |

Ultrasonic descaling & anti-scaling for heat exchanger in petrochemical plant. |

|

Ultrasonic descaling & anti-scaling for air compressor in refinery. |

|

|

| |

|

|

|

| |

|

|

|

|

|

| |

Ultrasonic descaling & anti-scaling for oxygen compressor in ethylene plant. |

|

Ultrasonic descaling & anti-scaling for sewage pipeline in treatment plant. |

|

|

| |

|

|

|

| |

• Spefication |

|

|

One set ultrasonic anti-scsaling processor consists of 1 set of drive power supply (controller), 8 set of ultrasonic transducers:

- Vibration Frequency: 20KHz ± 1KHz, frequency automatic tracking

- Maximum power: 4000 watts per unite (50 watts per set of transducer)

- Vibration mode: pulsing control

- Working environment: temperature 0-60 ℃, relative humidity ≤ 70%

- Input voltage: AC220V ± 10﹪, 50HZ

- Effective range: 10-50 square meters or 50-300 meters long pipeline.

In practice, different output power level of ultrasonic anti-scaling processor can be flexibly adapted according to the actual working conditions.

|

|

|

« Back |

↑ Top |

|

|

|

Downloads

Downloads Sitemap

Sitemap Downloads

Downloads Sitemap

Sitemap